| Sign In | Join Free | My benadorassociates.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My benadorassociates.com |

|

Place of Origin : China

Brand Name : Greatwall

Certification : ISO 9001:2008

Model Number : GR-50L

Price : $ 4,200 - $4,900

Packaging Details : wooden box

Delivery Time : within 7 days after receiving the payment

Payment Terms : T/T

Supply Ability : 200 Set/Sets per Month

MOQ : 1 sets

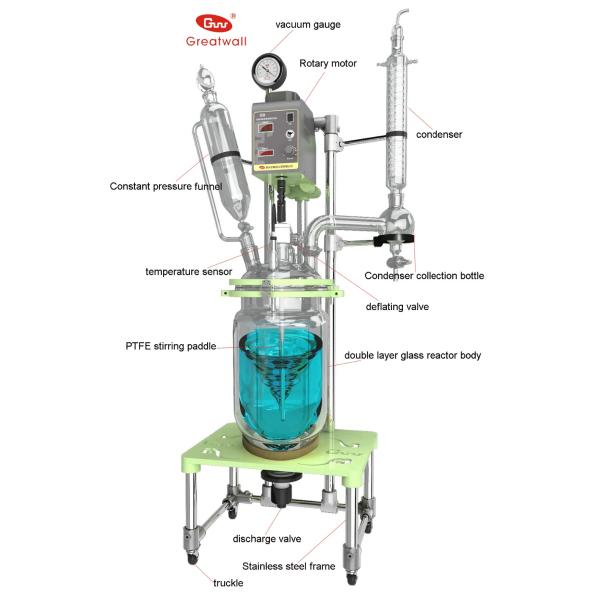

General structure of Biodiesel glass reactor GR-50L:

Usage of Biodiesel glass reactor GR-50L:

Reagents are set in the inner layer of double-layer glass reaction kettle, at the same time, vacuum can be taken out and mixing speed be adjusted. Interlayer can lead in refrigerating fluid, water and high temperature liquid to heat and cool the materials.

Application fields of Biodiesel glass reactor GR-50L:

It can be used in the experiment, middle-scale test, and production of chemistry, fine chemical engineering, biological pharmacy and synthesis of new materials.

Biodiesel glass reactor GR-50L can be equipped with:

The products can be made into system devices with multi-purpose circulating water vacuum pump, diaphragm vacuum pump, low temperature circulating pump(vacuum), circulating cooler, constant temperature circulator, low temperature cooling liquid circulating pump and closed cooling and heating circulating equipment.

Features of Biodiesel glass reactor GR-50L:

1.High borosilicate glass has good physical and chemical properties.

2.Can be used in wide temperature range from high temperature (200℃) to low temperature (-80℃).

3. Can work in constant pressure and vacuum, vacuum degree is below 0.095MPa in quiet situation.

4. Digital display of mixing speed, frequency conversion, and constant speed mixing system, work steadily.

5. PTFE mixing propeller (paddle).

6. Corrosion resistant discharge valve is without dead space design.

7. The cooling or heating solution in the interlayer can be completely removed after reaction.

Details:

Technical data of Biodiesel glass reactor GR-50:

| Model | GR-5 | GR-10 | GR-20 | GR-30 | GR-50 | GR-80 | GR-100 |

| Power(W) | 90 | 140 |

| 250 | |||

| Stirring Speed(rpm) | 50~500 | ||||||

| Max.torque(N`cm) | 132 | 200 | 200 | 273 | 378 | 378 | |

| Material capacity(L) | 5 | 10 | 20 | 30 | 50 | 80 | 100 |

| Interlining cover capacity(L) | 1.5 | 3 | 6 | 10 | 16 | 24 | 30 |

| The height of the discharge valve from the ground(mm) | 360 | 380 | 335 | 310 | 320 | 340 | 340 |

| Overall Height(mm) | 1780 | 2000 | 2030 | 2150 | 2240 | 2480 | 2480 |

| Reactor Material | High Borosilicate Glass 3.3 | ||||||

| Temp. ssensor material | Stainless steel claded by fluorine, double anti-corrosion | ||||||

| Temp. Range | -80~240℃ | ||||||

| Speed Control Method | Frequency Speed Control | ||||||

| Affordable jacket temp. difference between inside and outside | 110℃ | ||||||

| Inlet/outlet liquid circulation nozzle | DN15 | ||||||

| Power Supply(V/Hz) | 220/50 | ||||||

Explosion-proof Biodiesel glass reactor GR-50EX total system: